Glass enclosures are rapidly becoming the standard in mobile device design such as cell phones, tablets, and watches. This is primarily driven by the larger trend toward 5G connectivity, where the use of metal enclosures interferes with signal strength. Glass, shiny metal, and plastics pose a major challenge for quality control inspection as these materials are highly specular and not well-suited to traditional laser measurement technologies. This blog looks at our solution to this challenge based on the recently released Gocator® 2512.

The Challenge

Standard line profile sensors are highly sensitive to laser-angle and therefore unable to generate reliable data on specular surfaces. Coordinate measurement machines (CMMs) use probes that cannot measure the narrow gaps between the glass and frame. Confocal technologies are relatively large and expensive with limited fields of view and measurement range.

The Smart Solution – Gocator® 2512

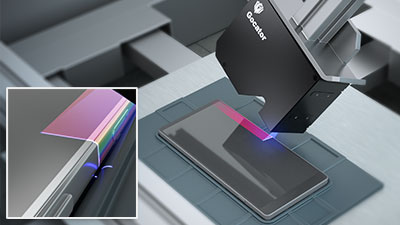

Gocator® 2512 is a smart 3D laser profiler optimized for scanning glass and other specular surfaces. This sensor is precision-engineered to overcome the limitations of standard line and point laser profile sensors, as well as CMMs and confocal scanners.

The 2512 delivers superior 3D data on glass and other specular surfaces, with complete inspection (i.e., scan, measure, and control) at speeds up to 10 kHz. In addition, specialized laser projection technology allows the 2512 sensor to be mounted at a variety of surface angles for superior performance on a wider range of specular surface materials (e.g., anti-glare, coated/uncoated, low/high contrast, transparent, glossy), and colors.

This smart 3D laser line profiler can even scan specular and diffuse materials simultaneously.

The Implementation

A Gocator® 2512 laser line profiler scans the edge of the glass in its frame, generating high-resolution 3D scan data, then applies built-in measurement tools to inspect for gap, flush, and offset.

The Benefits of Smart 3D

2D technology cannot be used for cell phone glass assembly inspection because 2D vision is unable to generate shape data. Gocator® 2512 sensors, in comparison, provide height information at a density which allows users to accurately identify and inspect surface edges and gaps between mated components (e.g., glass and frame) to within microns.